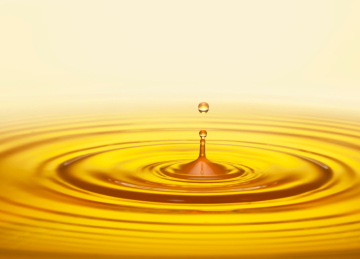

Unlocking Performance Insights: Lube Analysis Service

Gain valuable insights into the performance and condition of your lubricants with our advanced lube analysis service. Our state-of-the-art laboratory facilities and expert technicians analyze your lubricants to identify potential issues such as contamination, degradation, and wear particles. With detailed reports and recommendations, you can proactively manage your lubrication program, extend equipment life, and minimize downtime.

Frequently Asked Questions (FAQ) about Lube Analysis Service

Lube analysis involves testing samples of lubricants used in machinery and equipment to assess their condition, performance, and suitability for continued use. It is important because it allows businesses to monitor the health of their lubricants, detect potential issues early, and prevent equipment failures and costly downtime.

Lube Analysis Service begins with the collection of lubricant samples from your machinery. These samples are then analyzed in our state-of-the-art laboratory using advanced testing techniques and equipment. Our team of experts carefully examines the results and provides detailed reports with actionable recommendations to optimize lubricant performance and equipment reliability.

Our lube analysis process typically includes a range of tests to assess various aspects of lubricant condition and performance. These tests may include viscosity measurements, elemental analysis to detect contaminants and wear metals, infrared spectroscopy for chemical composition analysis, and particle counting for wear particle analysis.

Why Lube Analysis Matters

Unlock the Potential of Your Lubricants

Don’t leave the health and performance of your equipment to chance. Partner with Petro Trade & Industry for our Lube Analysis Service and take control of your lubrication program. With our expertise and commitment to excellence, we’ll help you unlock the full potential of your lubricants and ensure the continued success of your operations. Contact us today to learn more and schedule your analysis.